SIDEWALL

BELTING

Sidewall belting is widely used for bulk material lifting in harbor, metallurgy, tunneling, power plant, chemical industry, cement, and metro, etc.

The conveying capacity can be reached to 6000 m³ / h.

QBF Features

• Biggest sidewall belting manufacturer in China.

• International standard.

• Full set of European standard molds.

• Hot vulcanization.

• Big production range.

• Full range service -- belt selection, production, installation, splicing etc.

Base belt

Sidewall belts require a certain tensile strength and abrasion resistance. For belt must have enough cross rigidity and flexibility longitudinally to meet up with the requirement of deflection part of conveyor. The specially designed base belt with cross rigidity solved the problem of belt deformation. The belt standards are in accordance with international standards.

• QXE This belt incorporates the transverse polyester monofilament cords within the fabric, used for small and medium sized applications.

• QXE+2 The cross rigid and tensioning plies are separate, in this case the belt has 2 cross-rigid polyester monofilament plies, application areas are medium to heavy.

• QXE-SC+2 This belt incorporates textile tensioning plies with Bekaert steel breaker. The high transverse stiffness means the belt can be used in application areas where rigidity is a crucial factor, i.e. High lift heights and wide belts.

• QXST-SC* This belt incorporates steel cord tensioning with Bekaert steel breaker. High tensile strengths can be achieved making the belt ideal for high vertical lift applications.

Rubber quality

• Black Standard High Abrasion Resistant

• Moderate Oil Resistant

• Supper Oil Resistant

• Heat Resistant up to 120℃

• Heat Resistant up to 150℃

• High Heat Resistant up to 180℃

• Flame Retardant

• Cold resistant

• Other qualities may be available on special order, please enquire.

Sidewall

Rubber qualities

• Black Standard High Abrasion Resistant

• Moderate Oil Resistant

• Supper Oil Resistant

• Heat Resistant up to 120℃

• Heat Resistant up to 150℃

• High Heat Resistant up to 180℃

• Flame Retardant

• Cold resistant

• Other qualities may be available on special order, please enquire.

Fabric reinforcement

QBF sidewalls from type S120/MDSF120 and higher have special diagonal fabric reinforcement in the corrugations as standard, smaller sidewalls can have this feature if required.

Cleat

QBF cleats have been specifically design to give optimum performance.

The shape of the ‘C’ and ‘TC’ types has been created to offer the best conveying capacities along with excellent self-cleaning properties.

QBF cleats are molded with features of strong stiffness abrassion resistant and impact resistance to give the best shape retention even when conveying high-density materials.

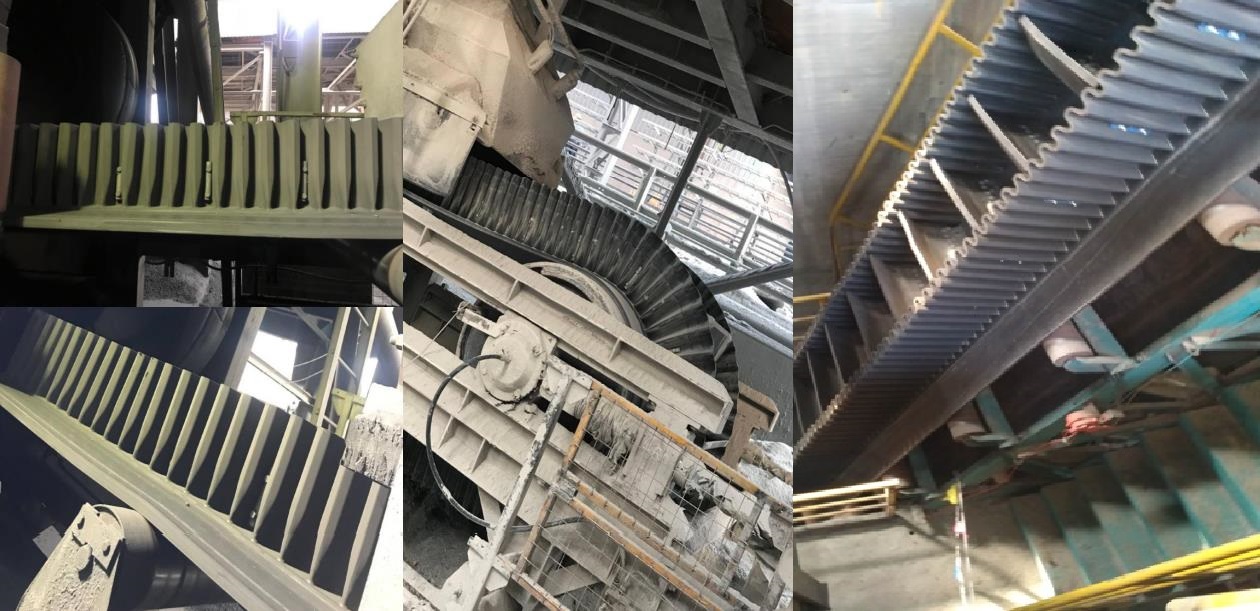

Sidewall belting

• Steep incline conveying from 0 to 90 degree

• No transfer points.

• No spillage with steep angle conveying.

• Maximum utilization of space.

• Minimum maintenance, long belt Life.

• Wide range of materials can be handled.

Manufacturing capacity

• Base belt: 300-2400mm

• Sidewall height: 40-630mm

• Cleat height: 35-600mm

• Belt strength: 250-7500N/mm

Hot vulcanization

QBF sidewall belting is assembled by hot vulcanization technology,

Which achieves super high adhesion value, non-fall off.

The adhesion won’t be influenced by high temperature material.

Automatic buffing machines present excellent adhesion value to ensure excellent adhesive strength.

Automatic cutting machines give accurate dimensions to ensure accurate specifications.

All QBF base belts, sidewalls and cleats are processed by our patent automatic machines.

Advanced computerised belt selection program

The appropriate belt specification can be designed through specialized belt selection program by our experienced team based on data of conveying application.

Please send us an enquiry, we will be pleased to select an optimum belt along with our commercial offer.

Remark: normal quality basis

Application

-Chemical-

-Steel mills-

-Cement-

-Power plant-

-Tunneling / Metro-

-Harbor terminal-